Like many companies facing pressure to adapt to the growth in big data and edge computing, colocation provider vXchnge is rolling out thermal management innovations in many of its U.S. data centers.

We recently spoke with Ross Warrington, Regional Vice President of Operations for vXchnge, about changes in their data centers and what they are doing to adopt new technologies for thermal management.

VERTIV: What kind of company is vXchnge?

VXCHNGE: vXchnge is an edge co-location provider. We focus on brand protection for our customers and we approach that with data center as a service.

In facilities management, the key business objectives relate to reliability, brand protection and cost control. We are a colocation company that delivers “Data Center as a Service” for our customers. Our mission is based on our commitment to protect and grow all brands regardless if they are global or just emerging.

VERTIV: What are your customers’ most pressing needs?

VXCHNGE: The most important thing for us is to be invisible to the customer, so they come to us for data center as a service and we want to provide that service with as little interruption to their business as possible. For us to be able to provide brand protection without causing the customer to have to do any work, is the key element. Another important aspect to our customers is their ability to scale. We meet that need for scalability and agility with extreme velocity.

We’re designing Edge High Density data centers, so when a customer comes in and they need to ramp up from a 2kW to a 10kW rack, or even a 20kW rack, that’s something we have built into our infrastructure. We’re ready to support that, and we don’t have to come up with a newer, creative solution that takes a long for them to deploy for their mission critical application. We’re ready to support that scale immediately because of the kind of data centers that we are building and the densities that are included in them.

VERTIV: Let’s talk about your rapid growth and key challenges in managing that growth.

VXCHNGE: vXchnge is positioned for rapid growth. We’ve amassed 14 data centers in less than three years and we want to be able to allow our customers to scale rapidly, so we pick the right vendors and partners to be able to do that.

Our number one job is brand protection for the customer, and the way that we execute on that is by hiring mission-critical experts and training them to operate our data centers to ensure no interruptions to our customers. We take personal accountability and responsibility seriously, and that’s key to brand protection in our strategy.

In order to sustain our growth, we’ve had to get some strategic partners to help us do so. Vertiv is one of those partners, and they’ve helped us to drive that growth with products such as the Liebert DSE free cooling system, which we installed in our Pittsburgh data center.

VERTIV: What are some innovative approaches you’re using in data center thermal management?

VXCHNGE: One of our overall goals is sustainability and energy efficiency, and one of the ways we accomplish that is by purchasing wind power, specifically for the Pittsburgh data center, where we have 100 percent wind power from Constellation Energy.

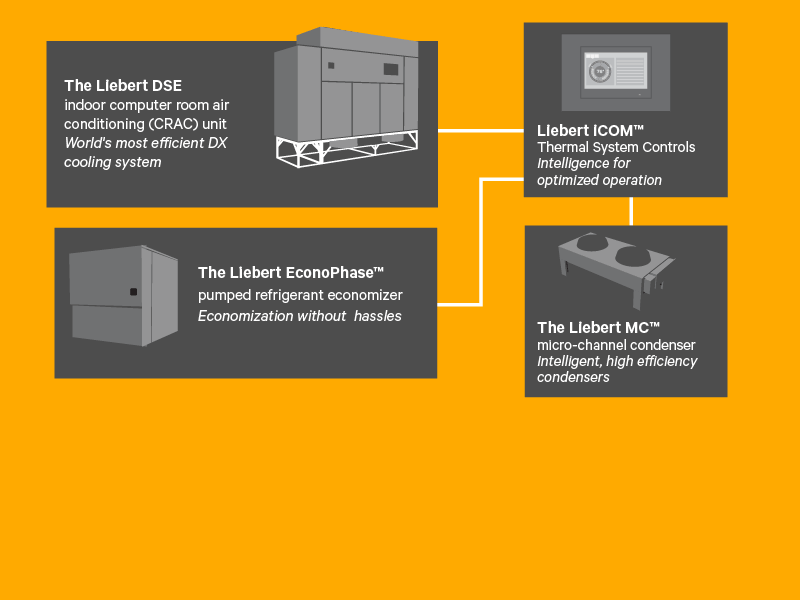

For data center thermal management, the innovative approach that we’ve chosen is the Liebert DSE free cooling system. We use that product along with the Liebert iCOM-S system control and we network and teamwork all of the CRAC units together using the iCOM-S so that we can collect all of the relevant data as well as the temperature sensor data at the rack level. That lets us make sure that our cooling is addressing our customer needs and SLAs.

The Liebert DSE is much quicker to deploy than a centralized chiller plant. A centralized chiller plant has tons of piping, a lot of connections and a lot of testing, whereas the Liebert DSE has a simple one to one ratio between the CRAC and the condenser. Those units come pre-packaged from the factory, all ready to go with the software already installed. They have the native functionality of an automation system so that we do not have to separately install the control software.

I would say that the main thing about the Liebert DSE is that there is nothing on the market like it. It is not a comparable product to anything else. I’m not aware of any other manufacturers that are using the pumped refrigerant economizer technology.

VERTIV: Describe the recent updates to the Pittsburgh data center.

VXCHNGE: Our Pittsburgh facility had nine, end-of-life CRAC units, which were legacy direct expansion (DX) type equipment with a mechanical PUE of around 2.0. The Liebert DSE system has a mechanical PUE of approximately 1.3. In the Pittsburgh market, it works particularly well using the pumped refrigerant economizers, because of the number of airside economizer hours you can get in the northeast region.

This region is very friendly for airside economizers, and to be able to use the Liebert DSE product ensures that we’re keeping the conditions inside the data center more stable. The Liebert DSE product also was recently approved under Title 24 in California, which was convenient for our Santa Clara location. The Liebert DSE in that data center allowed us to move away from chilled water technology. It’s more efficient, it’s easier to deploy, and more resilient and redundant than a centralized chiller plant. So we’re very excited about that new Title 24 approval in California.

VERTIV: Would you describe your monitoring and control challenges in the data center?

VXCHNGE: We specialize in micro-data centers and data center as a service, offering our industry leading customer portal that allows customers to manage their own environment - everything from access control to power utilization monitoring, temperature monitoring inventory management, and even RFID.

Data center infrastructure management (DCIM) is actually key to our data center as a service approach. We’re using it in a lot of ways. We actually pair our DCIM system with our inventory management, with our data bases, with RFID, and with all of our monitoring technology. Using products with granularity that we can pass to our customers, improves how they manage their colocation environment. Those are all good products for us and products that we would leverage in our DCIM platform.

VERTIV: How does Liebert iCOM-S thermal system control software help meet your challenges and what’s been the biggest impact since installing it?

VXCHNGE: We chose the Liebert iCOM-S to address our monitoring and control issues. Besides being able to collect and aggregate a lot of data, the Liebert iCOM-S also uses that data to make intelligent decisions about cooling, to ramp the fan speeds up and down on our CRAC units, to cascade additional units if there is a temperature issue, to rotate our units for even run time, and also to give us data about our units to know if we have any alarms, issues or monitoring problems.

iCOM-S has been extremely efficient and effective for us, and the best example is not only in our new data centers but in retrofit situations. We installed the iCOM-S in our Santa Clara, California data center which was already a very efficient facility. What it allowed us to see is that we have a great ability to reduce fan speeds even more than we realized. We didn’t know that until we installed the iCOM-S and paired it with the temperature sensors that gave us the granular data we needed to do the best tuning for our data center.

The nice part about iCOM-S is not only that it collects that data, but that data is actionable, and the system uses it to reduce fan speeds and gain efficiency, so we have seen a lower PUE in our data centers. With the combination of the Liebert DSE and the iCOM-S, we’re seeing some significant efficiency gains, somewhere in the neighborhood of 30%, depending on the application.

The iCOM-S is also unique from a deployment perspective. In past deployments, we’ve had to pair a third-party control system with our own technology for thermal management. There was no one package that gave us the sensors, the CRAC units, and also the control and automation together. So what we like about iCOM-S and what we find is unique is that it’s an OEM solution that pairs nicely with other OEM products that we’re already using.

VERTIV: Thank you, VXCHNGE!

- Learn how to achieve industry’s highest efficiency operation with the Liebert DSE

- Learn how to manage and control your entire data center cooling system for up to 50% higher efficiency more with the Liebert iCOM-S Thermal System Control