New electrical code changes mandate maintenance for electrical equipment. It is a well-known fact that a good preventive maintenance strategy is critical to optimizing equipment performance, reliability and uptime.

Electrical equipment maintenance also plays a key role in improving worker safety, which is why today’s leading electrical safety consensus codes and standards emphasize maintenance best practices. In the most recent versions of the National Fire Protection Association’s Standard for Electrical Safety in the Workplace© (NFPA 70E), changes have been made to articles 200 through 250, which address maintenance requirements for industrial facilities, data centers, and other workplaces. The changes increase the scope of electrical equipment maintenance, ultimately creating a safer work environment and protecting workers from the ever-increasing risk of electrocution and arc flash incidents. Additionally, updates to the code specify that the equipment owner is now responsible for the maintenance, as well as the documentation of maintenance activities. Below are some tips that can help you take responsibility and action to ensure compliance, protect your workers, and safeguard your business.

1. Maintain All Your Electrical Equipment,Not Just Overcurrent Protective Devices

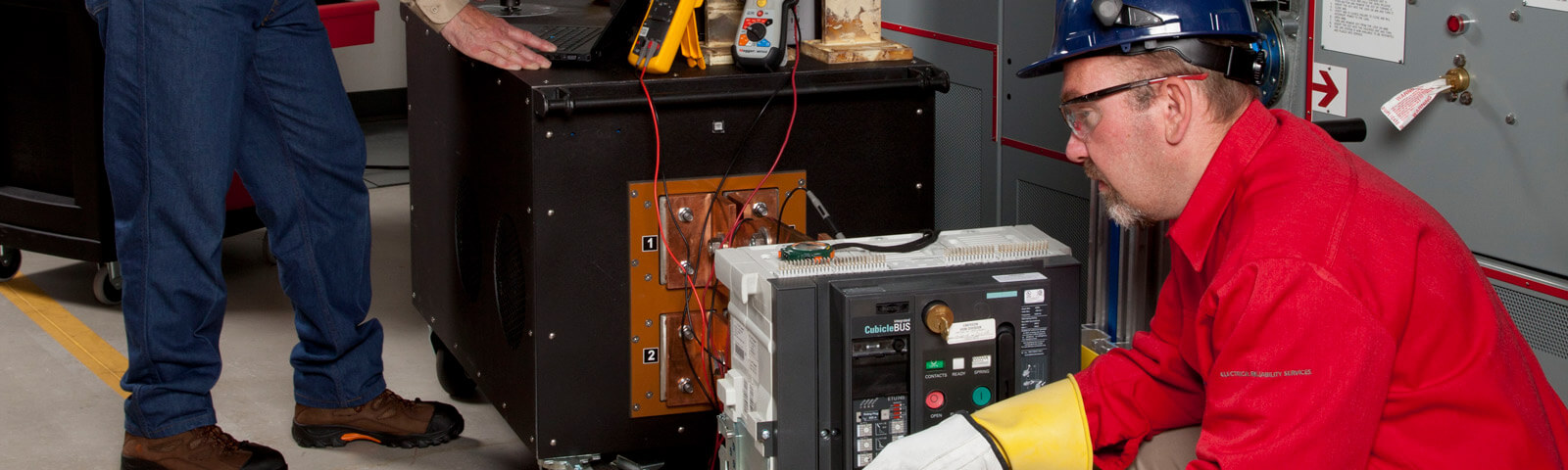

Previously, NFPA 70E specified maintenance only for overcurrent protective devices. Today, the standard requires facility managers to conduct maintenance on all types of electrical equipment in accordance with manufacturers’ instructions or industry consensus standards, such as American National Standards Institute/InterNational Electrical Testing Association Standard for Maintenance Testing Specifications (ANSI/NETA MTS), Institute of Electrical and Electronics Engineers (IEEE) 3007.2, and NFPA 70B. Equipment that should be maintained includes:

-

Substations, switchgear assemblies, panelboards, motor control centers, and disconnect switches

-

Insulated conductors, grounds, and bus ducts

-

Transfer switches and control equipment

-

Circuit breakers

-

Protective relays

-

Motors and generators

-

Equipment in hazardous locations

-

Batteries and battery rooms

-

Portable electric tools and equipment

-

Personal safety and protective equipment including electrical gloves, hot sticks, and flash suits

2. Maintain a Current Single-Line Diagram in Legible Condition

Accurate, up-to-date single-line diagrams are essential for documenting, troubleshooting, and communicating information about a facility’s power systems. NFPA states that single-line diagrams shall be maintained in a legible condition and shall be kept current. A comprehensive site survey can be instrumental in developing or updating existing single-line diagrams or completing electrical system drawings.

3. Document Maintenance for Overcurrent Protective Devices

The standard also mandates that overcurrent protective devices shall be maintained and that the required maintenance, tests and inspections shall be documented. Such documentation can confirm the actual settings and equipment condition/operability—information that could be crucial during investigation of an arc flash-related injury, equipment failure, or unplanned shutdown.

4. Train Workers Who Perform Maintenance

Maintenance work is only as effective as the people who perform it. NFPA 70E 2015 states that persons who perform maintenance on electrical equipment and installations must be “qualified” (as defined in 110.2) and they must be trained in and familiar with the specific maintenance and test procedures required. Additionally, the standard stipulates regular retraining, documentation of training, and annual worker audits for all employees working on or around electrical equipment.

5. Use Decals to Provide Instant Access to Maintenance Status

Many facilities use test or calibration decals to provide employees with immediate indication of the latest maintenance date and maintenance status. The decals also include the overall condition of the device to assist employees in the assessment of equipment condition.

6. Consult the Recommended Maintenance Guidelines

The latest edition of NFPA 70E added IEEE 3007.2 Recommended Practice for the Maintenance of Industrial and Commercial Power Systems as a guideline for maintenance frequency, methods, and tests, along with NFPA70B and ANSI/NETA MTS.

Putting Your Maintenance Program Into Action

It can be challenging for facilities to comply with the increasingly stringent electrical equipment maintenance requirements outlined in NFPA 70E. However, a professional electrical engineering or electrical testing service provider can help with creating a cost-effective and manageable maintenance program that ensures compliance with the standards. Such a program supports system performance and efficiency, and prevents costly fines. It can also reduce injuries and lost worker productivity, and even save a life.