Airflow Conditioning

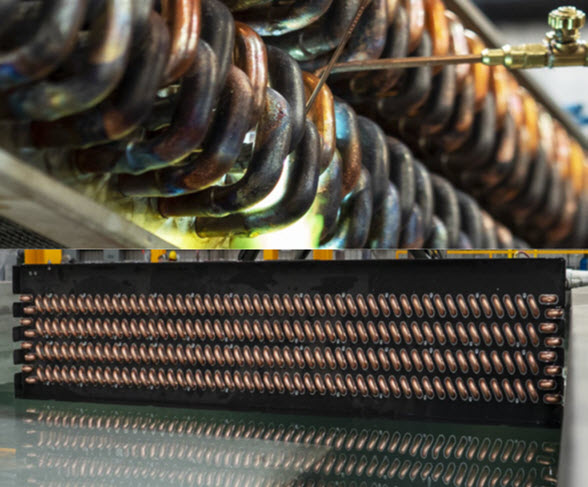

Coils

We offer, design, and manufacture a robust line of coil solutions including Chilled Water, DX, Hot Water or Steam Coils. Coils are built using the following materials

- Copper tubes of various diameter and gauge, with fins made of Aluminum or Copper material (ElectroFin Coating Available)

- Brazed or bent return bends options available, based on tube thickness

- Stainless steel casing standard on all cooling coils

- Coils >48” tall include a unique drain pan design built into fin pack

Heaters

Wide variety of heating solutions to meet customer’s requirements. Offerings include:

- Steam coils

- Hot water coils

- Indirect Fired Gas Heat

- Integral face and bypass dampers

- Other solutions can be provided with support of a Systems Applications Engineers

Humidifier

Steam injection manifolds can be provided to meet humidification requirements. Each section is supplied with factory installed distribution grids and stainless-steel drain pans to ensure safe operation and quality airflow.

Fan Systems

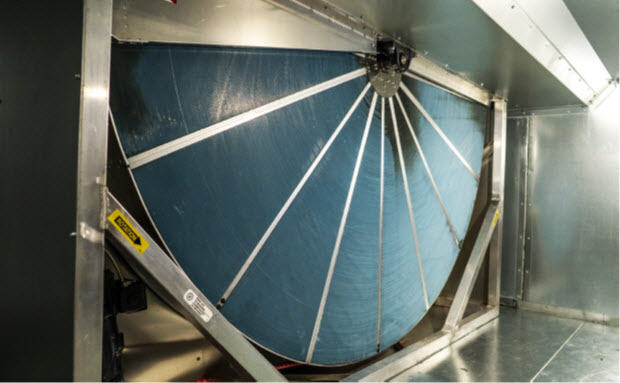

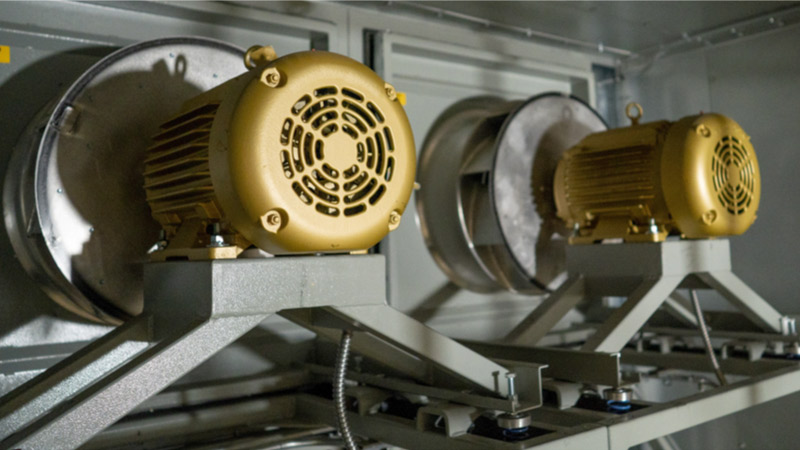

Optiline HE Fan Systems

Optiline HE fans feature a fully welded aluminum airfoil blade design for efficient and quiet operation, available in a single or multiple fan configuration. Multiple fan configurations are frequently the best choice as they offer many valuable system benefits, including:

- Optimum Energy Efficiency

- System Redundancy & Reduced Service Downtime

- Improved Acoustical Performance

- Reduced Unit Footprint

Spring Isolators

Spring isolators with seismic restraints are mounted on all Optiline HE Fan Systems, capable of satisfying OSHPD and IBC requirements (others can be reviewed).

Fan Wheel

All Optiline HE Fans include a fully welded fan wheel, that is designed, built, and paired with a motor to match the project ambient and airflow requirements.

Flow Trac™

The Energy Labs, a Vertiv™ Company Flow Trac system measures air flow rate. Using the fan inlet cone as a calibrated nozzle assures the airflow and sound levels are not affected by obstructions in the flow path.

IAQ Options

Modern buildings require ventilation rates to comply with ASHRAE Standard 621 as well as Good Indoor Air Quality (IAQ). Poor IAQ has been directly associated with “sick-building syndrome”, which can result in high illness rates, absenteeism, reduced productivity, and employee turnover.

IAQ Condensate Drain Pans

- Double-sloped design to prevent standing water

- Pans completely cover the coil plenum section width

- Pans are insulated with spray foam

- Fully tig welded construction

- Stainless steel drain connections and piping

- Available in threaded NPT connections

Surface/ Airflow Sterilization

A flexible and effective offering for surface and airflow sterilization

- Surface Sterilization

- UVC irradiation provides low intensity, full-time irradiation of the coil and drain pan surfaces

- Proven effective as a low energy demand, disinfectant for surfaces

- Airflow Sterilization

- Solutions, such as bipolar ionization, can be reviewed and supplied

- Work with a Systems Applications Engineer for more details and design support

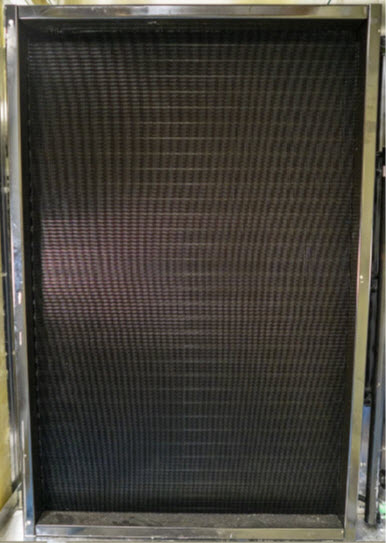

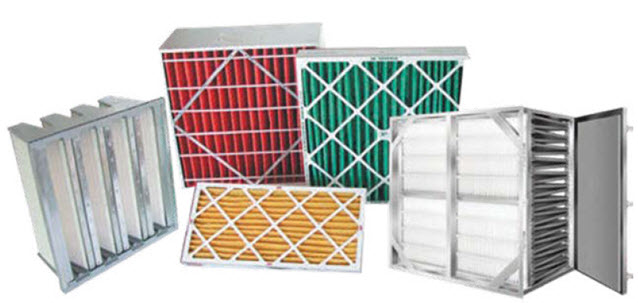

Filters

Filter options to meet project requirements, including:

- Panel filters

- HEPA filters

- Carbon filters

- Electronic filters

- Roll filters

- Bag filters

All filters and filter frames are selected and designed to allow for service access.

Electrical Component Options

Factory Installed Controls

The Vertiv iCOM 3 control system platform is offered as a standard. Requests to integrate other Building Automation System supplier’s controls systems can be reviewed. Most, if not all, controls components are factory installed and tested, which reduces commissioning time and cost.

- Control device | Sensors | Actuators | Flow Dampers | Etc.

- Most, if not all, wiring is pre-routed in conduit/trough per Energy Labs, a Vertiv™ Company standards

- Point-to-point wiring diagrams provided with unit drawings

- All penetrations are made and sealed in the factory

Fan Speed Controls

Fan speed control offers the most efficient method of varying air volumetric flow. The ability to control fan motor speed allows customers to optimize the design while maximizing energy savings through dynamic cooling loads. Options include:

- Variable Frequency Drives for Non-EC fan arrangements

- Single drive per fan motor

- Singe drive per fan array (multiple fans)

- EC fan arrangement

- Fan/motor arrangements are supplied with an integral speed control device

- Fan/motor arrangements are supplied with an integral speed control device

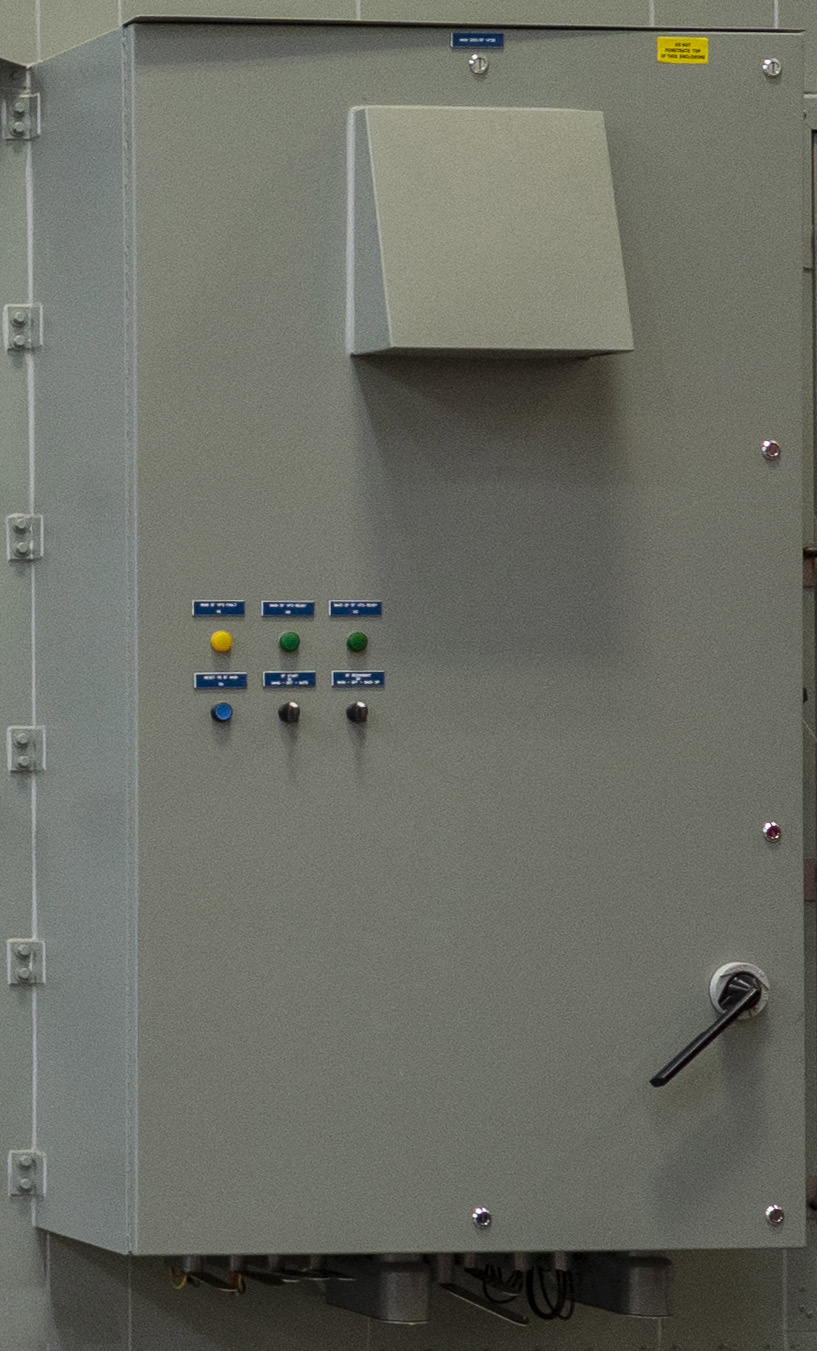

Single-Source Power Panel

To simplify the installation and improve quality of the electrical supply, single-source power panels are included as a standard. This allows field connections to be minimized to a single power connection, reducing site wiring, and testing efforts.

- Features:

- Disconnect Switches

- Fuses and relays

- Starters

- Transformers

- H-O-A Switches

- Pilot Lights

- Ratings:

- NEMA 1 | 3R | 12

- Listings:

- UL508A

Airflow and Sound Control Options

Dampers and Louvers

High performing low leak dampers and outside air louvers are available as needed. The low leak dampers and air louvers are designed in accordance with AMCA 511 and rated for pressure drop, leakage, and water penetration.

Airfoil design includes

- Aluminum airfoil to minimize pressure drop

- Minimizes noise levels by reducing air movement friction across the blades

Low leak design features

- Neoprene blade seals

- Stainless steel side seal

- Overlapping blade edge for secure shut off, preventing damper over travel

Construction

- Galvanized steel frames

- Robust linkage systems

Options

- Factory mounted actuators

- Locking quadrants

Sound Traps

Sound traps can be designed for any application with noise restrictions. Available sound traps include:

- Low Frequency traps

- Convention sound traps

- Sound traps with Mylar film covering the fill

- Packless sound traps, for applications where fiber airstream contamination is a concern

Energy Recovery Options

Energy Recovery

Modern buildings require ventilation rates to comply with ASHRAE Standard 621 as well as Good Indoor Air Quality (IAQ) to keep occupants happy and healthy.

- Poor IAQ has been directly associated with “sick-building syndrome”, which can result in high illness rates, absenteeism, reduced productivity, and employee turnover.

The challenge with Energy Recovery is balancing the efficiency gains with the energy consumption. To aid with this selection, Energy Labs, a Vertiv™ Company experienced applications engineers can help customers select one of the AHRI listed energy recovery systems to ensure customers get the performance required. Energy Labs, a Vertiv™ Company offers the following AHRI listed energy recovery solutions:

- Evaporative cooling

- Energy recovery coil loops

- Heat pipes

- Energy recovery heat exchangers

- Energy recovery wheels