Misconceptions have a habit of persisting – especially in an era of ‘fake news’.

Take for example the idea that the order in which you might drink wine or beer has some effect on how hungover you feel the next day. Beer before wine is fine but wine before beer? Oh, dear.

The reality is that it’s a lot more about how much alcohol you consume and not the order you consume it in. Most people probably know deep down that it’s a nonsense but are still happy to trot out the advice, or attribute their own sore head to an unscheduled glass of Chablis.

The truth is that a lot of decision making is instinctive and based on long-held beliefs rather than being as coldly logical as we might like to believe. And despite the wealth of intelligence and research available that also goes for decisions made at work (as well as at the bar).

The data center industry, like other sectors, has its fair share of misconceptions, myths and commonly-held beliefs. The fact that it is an industry that is largely predicated on maintaining resiliency and uptime often means that conservative, established-thinking, often take precedence. It’s better to be safe (and stay with what you know) than be sorry (invest in something new or untried).

As a result, there are whole range of emerging, and potentially disruptive technologies, that have the promise to improve efficiency and effectiveness but risk being stymied by outdated, or just plain-wrong, groupthink.

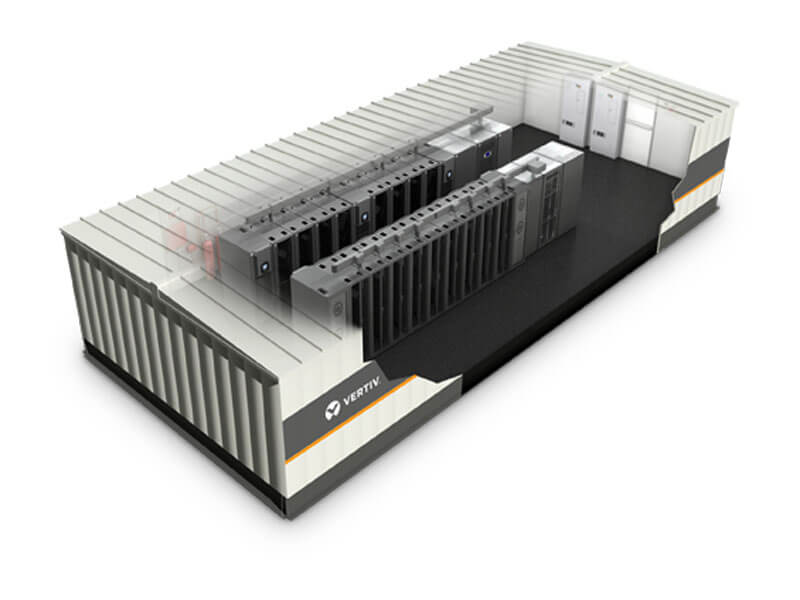

Take prefabricated modular (PFM) data centers for example. Rather than conventional – or stick builds – which rely on a lot of on-site construction, PFM involves assembling units or modules of data center infrastructure in factories and then shipping them to the site.

The technology has been around for more than a decade – and a lot longer outside of the data center. It also continues to evolve, with more and more suppliers developing new technology and services.

Despite that legacy, and continued innovation, misconceptions about PFM data centers persist including that the technology is still unproven and that it hasn’t evolved from early designs.

Logic, facts and proof don’t always trump established thinking but let’s take shot; it’s time to puncture some of those misconceptions:

PFM data centers are a niche product

Yes, PFM facilities still occupy a relatively small part of the market. But that slice is only set to grow. Demand from colocation providers that like the agility – ability to add capacity as required - as well as future demand for new edge micro-data centers related to 5G are just some of the drivers. According to industry analysts 451 Research, the market for PFM data centers is set to expand at a five-year compound annual growth rate (CAGR) of 14.4 percent through 2021 when it will have reached $4.4bn. “PFM methodology is becoming the preferred way to expand and build new data center capacity, turnkey or critical subsystems. Underpinned by industrial processes, it has distinct advantages in terms of quality control, installation speed and build consistency” said Daniel Bizo, principal analyst 451 Research recently.

PFM data centers are just containers

The fact that the first wave of PFM products from IT companies such as Sun Microsystems were based around ISO containers has meant that this form-factor has continued to be closely associated with the term PFM – perhaps to the detriment of wider uptake of the technology. Even though PFM now encompasses the full spectrum of data center infrastructure - from rows, to rooms to full facilities as well as power and thermal infrastructure - the perception that PFM = containers persists. The continuing challenge for data center industry is to communicate the breadth and flexibility of design that PFM can enable.

PFM is more expensive than conventional builds

One of the most powerful benefits of a PFM data center is that it does not require the value of faster deployment to be weighed against the additional costs commonly associated with faster delivery. PFM data centers leverage economies of scale and streamlined processes made possible by offsite assembly to enable faster deployment at a lower TCO. The economics of PFM are so attractive that they can change the cost-benefit analysis regarding expanding an existing facility versus a new build. A PFM data center may enable an organization to move a data center to a more desirable location at about the same cost as expanding and updating an existing facility.

PFM facilities are less resilient and/or secure

Yes, some PFM form-factors, particularly container-like designs, or even micro-data centers are portable; they can be delivered on the back of a truck and, if required, moved to another location. But that portability has no bearing on physical security or resiliency. When surrounded by the same physical security barriers – fences, man-traps, guards – as conventional builds, PFM facilities are just as secure. In fact, PFM facilities are also arguably less prone to failures because the crucial testing, and even some commissioning, can be done under factory conditions. Pre-integration of components also means that maintenance problems emerging from components not being installed properly are also reduced. Finally, on the issue of resiliency, the main certification organisation for the data center industry, Uptime Institute, has developed its Tier-Ready programme to streamline the certification of facilities built in part, or in total, using PFM components.

PFM is just about whitespace

PFM isn’t only about replacing stick-build techniques wholesale. PFM is a flexible technology that can be used to augment conventionally constructed facilities. For example, specialist PFM units can be deployed to add additional power (UPS) or cooling capacity to an existing site that may have sufficient whitespace but is constrained from a thermal or resiliency perspective. A specific example of this technology in action is Vertiv’s Power Module product family. Power Module is designed to be deployed in new or existing facilities that require an agile and flexible way to scale-up power distribution and resiliency.

PFM facilities look ugly

PFM designs are applicable to everything from entire facilities, which are indistinguishable from conventionally-built sites, to single-rack micro-data centers to support edge compute requirements that can be integrated into a beautifully designed office building. A good example of the former is T-Systems’ Cerdanyola del Vallès data center in Barcelona. Although built using a PFM approach, from the outside it looks exactly like a conventional building. It is currently one of the largest modular data centers for T-Systems in Spain, with a modular IT load capacity of 1.1 MW, scalable up to 5 MW in future phases. The facility also received the Data Centre Market award for most innovative project in Spain, and has been recognized by the Uptime Institute for providing 99.98 percent availability.

For more on why prefabricated data centers may be the right approach for your next edge, core, colocation or telecoms datacenter check out the whitepaper: Prefabricated Modular data centers: from disruption to default option.