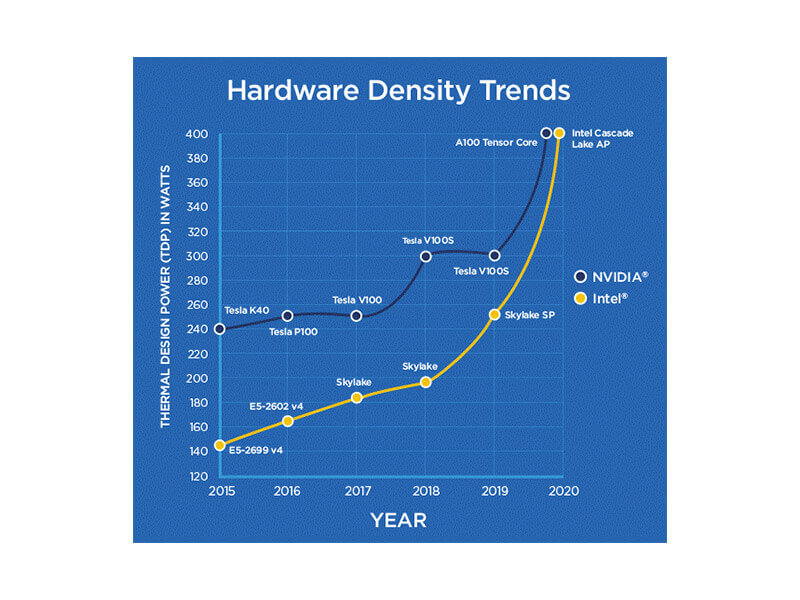

We All Know Where Data Center Demands Are Heading – Up.

We also know what’s driving the demand: continual changes in rack density (heat and power) to keep pace with high-performance computing trends, including artificial intelligence and machine learning.

But there’s a problem. Traditional technologies like Rear Door Heat Exchanger (RDHx) and Liquid to Chip (LTC) are merely band-aids for legacy air cooling, and can only take heat rejection, power requirements and future flexibility so far.

Intel, NVIDIA, and AMD are producing chips running at 400,

Intel, NVIDIA, and AMD are producing chips running at 400,

and soon to be 500, watts.

What’s the Answer? For CGG, It Was Single-Phase Immersion Cooling

In 2010, global geosciences leader CGG dove into single-phase immersion cooling and hasn’t looked back. At the time, its aging 10,000-square-foot legacy data center in Houston, Texas had been mothballed due to obsolescence – suffering from a limited available power envelope and an extremely inefficient Power Usage Effectiveness (PUE) of >2.0. CGG’s goal was to retrofit the data center without any downtime to other systems or their network, minimize capital expenditures by deferring them over time, and limiting ongoing OPEX.

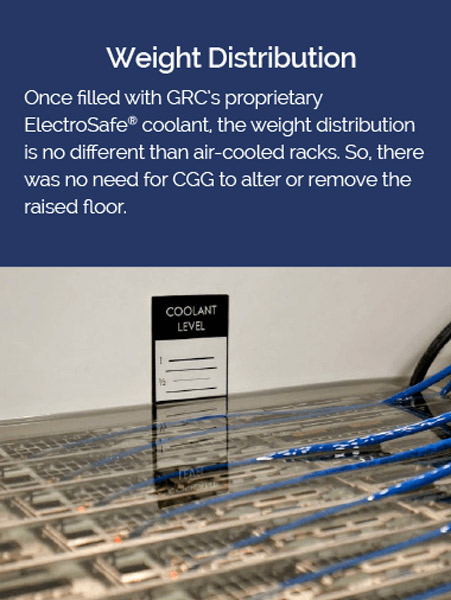

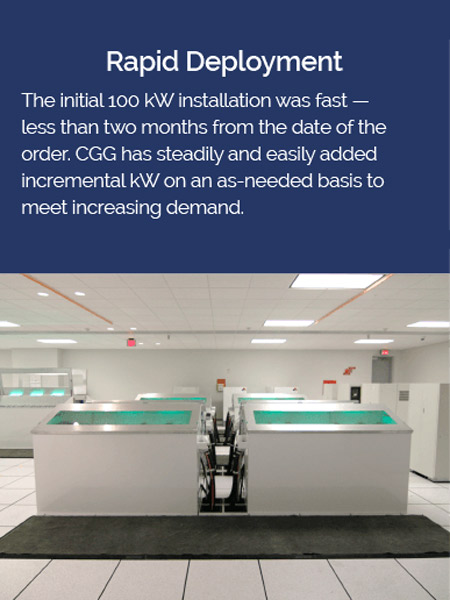

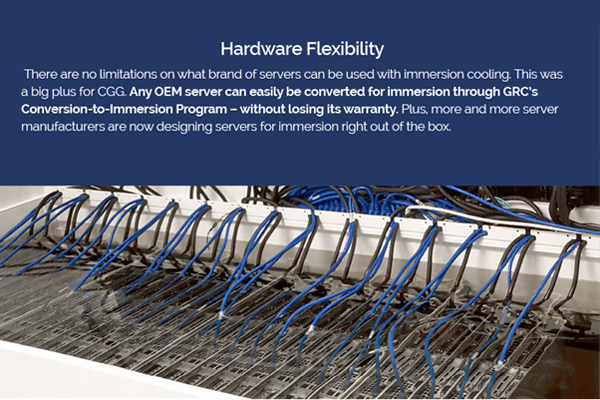

After careful analysis and consideration, CGG selected GRC’s patented immersion cooling solution, ICEraQ®, due to its unique ability to meet all its stated goals. The tailored solution included 4 x 42U racks with a 100 kW cooling capacity (25 kW/rack), all of which was installed within eight weeks of issuing the purchase order.

An Inside Look at the Process

Simple Day-to-Day Operations

Of course, the adoption of immersion cooling also brought certain changes – but CGG was impressed with those, too. Some changes truly made things easier; others, just different.

The Updated Environment: Calm, Cool and Quiet

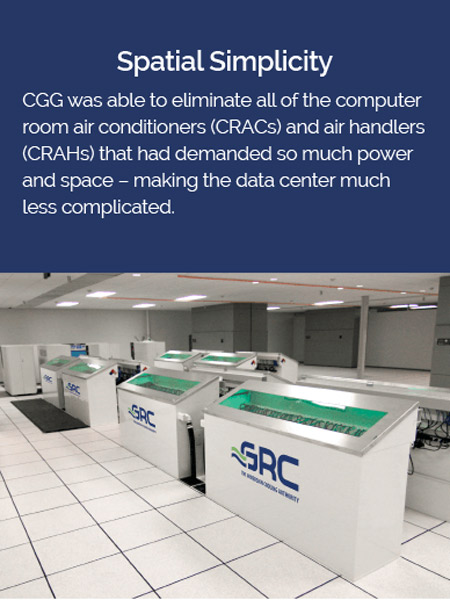

After installation, even more benefits became apparent to CGG. Traditional air-cooled data centers often feel like cold, noisy wind tunnels – and require a lot of space. CGG’s upgraded data center is just the opposite. It’s half the size of a comparable kW air-cooled data center. It’s also nearly silent, maintained at a comfortable temperature, well-lit, and organized to view all the ICEraQ systems and CDUs at a glance.

In fact, the whole layout is more ergonomic, technician- and human-friendly overall. Cables are neatly stored in the back of the racks; and racks are spaced for convenient access, not temperature control.

The racks themselves are equally remarkable. Dip your hand in the ElectroSafe coolant, and it feels like a warm bath (and you can, because it’s completely safe.) No matter how hot the equipment runs, the coolant will keep all component temps consistent—within 3 degrees. Mission accomplished.

Hear it Straight From CGG:

“Today there is not really much difference between managing this room and managing another traditional air based computer. Some of the differences as you can see because we’re right in the middle of this room, and it is producing as we speak, there’s no noise, almost no noise, the temperature is very reasonable,

there’s no air draft, there’s none of the things you would normally associate with a very high density computer. So that makes for a much nicer environment overall.”

— Laurent Clerc, VP of Information Technology at CGG

Conclusion: It’s Hard to Argue with Silence.

According to CGG, immersion cooling is different, but a better different – simpler, quieter, plus a lot more cost-effective and space-saving than other cooling methods. Best yet, CGG was able to save on both CAPEX and OPEX costs.